While contract manufacturing is not a new concept, its reach continues to increase. Companies large and small across the Automotive, Aviation, Electronics, and Food sectors effectively use contract manufacturing to better serve their customers and gain competitive advantages. For small and mid-size companies, in particular, contract manufacturing provides the ability to compete in cases where they lack the necessary manufacturing economies of scale.

Of course, when you’re outsourcing production partly or wholly to a third party, you have to be fiercely diligent about accounting for all the moving parts: materials, people, teams, quality, supply chains, product cycles, etc. This is where the dynamics of managing and overseeing production processes get tricky.

Project Management Challenges

Most Contract Manufacturers (CMs) and Original Equipment Manufacturers (OEMs) rely on tools such as Microsoft® Project to track tasks, dependencies, and timelines. However, traditional tools such as Project fail in a few key areas. First, they do a poor job of driving collaboration because they aren’t accessible by everyone on the team. Second, schedules driven by fixed start and end dates are too rigid to accommodate the changes inherent to project and production work. Third, as priorities change there’s no easy way to make those updates and see it automatically reflected in the project schedule.

A problem that crops up often is that CMs can’t keep up with the changes happening in the product specifications or OEM priorities. This is because the OEM lacks a central location that serves as the single source of truth about project plans and associated documentation. While project plans are originally built with the best of intentions, updating them is so labor-intensive that teams often give up on them, and work migrates to the inefficient silos of email inboxes and spreadsheets.

This lack of CM visibility into OEM’s priorities and OEM’s visibility into CM project statuses introduces a significant amount of risk into the supply chain and delivery dates. Both OEMs and CMs can end up getting information too late in the process to make corrections; and even when they do get or share information in a timely manner, deterministic systems such as Project make it difficult for teams to change priorities and reallocate resources.

This problem is exacerbated when production takes place in plants located in different time zones. And all the more so when the project deals with the introduction of a new product as opposed to continuation or optimization of an existing product.

Keeping Up With the Speed of Innovation

What CMs and OEMs need is a project management system that lets them build productive and profitable relationships and keep up with the speed of innovation. Using conventional software like Microsoft Project, or spreadsheets, where rigid plans built on guesstimates and best-case scenarios just don’t cut it. Dynamic Project Management presents a better alternative.

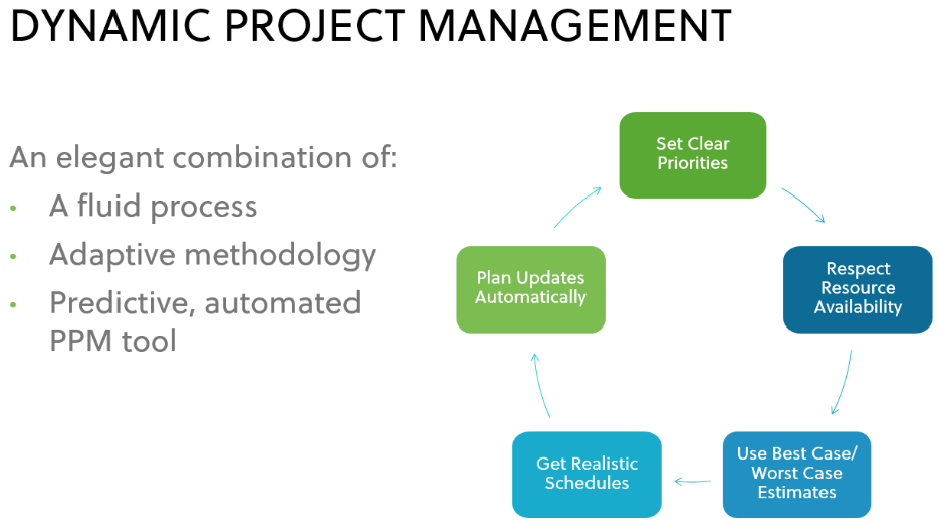

The philosophy behind Dynamic Project Management is that projects are living, evolving constructs. Therefore, teams need a way of planning and scheduling projects that maps to the real world. There are three key ingredients that make this happen: A fluid process; an adaptive methodology; and a predictive, automated tool.

Start With People and Priorities

In reality, people and priorities drive schedules. Project plans in the Dynamic Project Management system are built by starting with priorities and then marrying these priorities to task estimates and resource availability. Because of this approach, schedules are more realistic; teams work on the most important thing at the right time, and nobody’s assigned unrealistic amounts of work. Teams can also see and mitigate risks much earlier than they would with a traditional tool. It’s like going with, instead of against, the current of the project lifecycle.

A Single Source of Truth

A Dynamic Project Management tool such as LiquidPlanner gives all team members a central location to track and manage activities and resources. For project managers, this means having instantaneous visibility into project statuses and issues. For project contributors, it means always knowing what they’re supposed to be working on at a given time and being able to find all the information needed for that work in one place.

Responsive and Adaptive

A Dynamic Project Management system is based on a priority-based scheduling engine that takes tasks, ranged estimates and resource availability as inputs and translates these data points into expected completion dates. Along with producing these predictive finish dates, the schedule updates automatically as priorities or resource availability changes. CMs and OEMs can see what’s coming down the pike before disaster strikes; the right people can be alerted to any issues that need attention, and the schedule automatically updates with every priority shift and plan change. The result? No surprises and projects that deliver on schedule.

Could you benefit from adopting the Dynamic Project Management system?