There is a consensus among leaders and managers – supply chain problems are enormous, causing steep expense increases, loss of business opportunity, and customer frustrations. The pandemic has exacerbated this problem, and uncertainty and change seem to be the only sure things. At first, we experienced shortages due to the lack of material, like wood for paper towels and toilet paper, which led to hoarding. This drove the demand through the roof, and forecasters believed this would be the new normal. Trees were cut rapidly, new manufacturing plants were built, and more people were hired to meet the demand.

Less than three years later, demand is down, almost to its previous levels. Now we see the “bullwhip” effect. Costco and Sam’s Club are filled with pallets of toilet paper, and those newly built paper plants are shutting down. Forecasters now believe this downward trend may continue, so they don’t order as many paper products as before, and now another shortage ensues. If you draw a diagram of these decisions, it will look like the whipping effect of a “bullwhip,” thus the name. Whether it’s too much inventory or too little, the reason is the same: the supply chain.

This bullwhip effect may look chaotic but is fairly logical and predictable. This is due to the common element of a forecast, which is essentially an educated guess based on available information known at the time a decision is needed. This is called “Forecast Planning,” where the forecaster hopes their guess is correct, and then all the planning in the organization stems from this educated guess. A lot of people use this forecast to make critical business decisions. The forecaster’s job is one of the most challenging jobs in a company because their prediction is always wrong, and so many people rely on the accuracy of this number. So, most people in an organization are highly critical of forecasters.

Any planning you do without a variance can’t be accurately forecasted in times of uncertainty. In these instances, you have to base decisions on the actual demand to maximize the use of scarce resources. The errors in forecasting the unknown in times of uncertainty are not minor. But we can incorporate uncertainty into our demand plan with LiquidPlanner.

How can you avoid the bullwhip effect?

Demand Planning, based on Demand Driven Material Requirements Planning (DDMRP), must consider both demand variability and lead time. LiquidPlanner allows you to specify dependencies and successors in your planning to ensure the timeline includes the length of time to acquire the needed product from the supplier. Understanding the lead time with more confidence is one unique feature of LiquidPlanner’s demand planning engine that delivers timeline predictions with 90% confidence by using the power of Planning Intelligence.

In Demand Planning, the forecast is replaced with a “What If” scenario. Now that we know the best-case and worst-case variation, we look at the upcoming demand and then let the scheduling engine calculate when we need to order new materials. The most significant uncertainty risk in our supply chain example is at the docks. Incorporating this uncertainty into our demand planning schedule gives us a competitive advantage by providing more realistic timelines.

Optimizing Demand Planning

Lead time can be enhanced in real-time by actual data as changes occur. One of the realizations you may have as you begin to examine the demand plan is that the predicted lead time often is shorter than the actual lead time. You can use these insights for the next forecast to incorporate more uncertainty into the timeline.

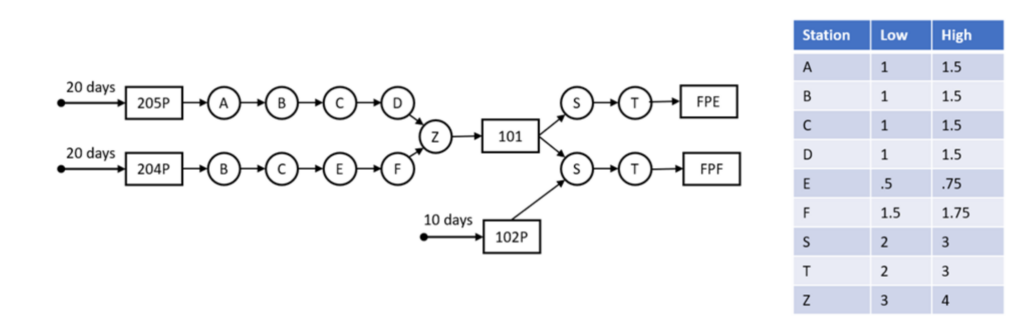

But how can we forecast a new scenario at the beginning of a new product or process? Let’s find out by using an example in LiquidPlanner. Here is a representation of a manufacturing system along with purchasing lead time.

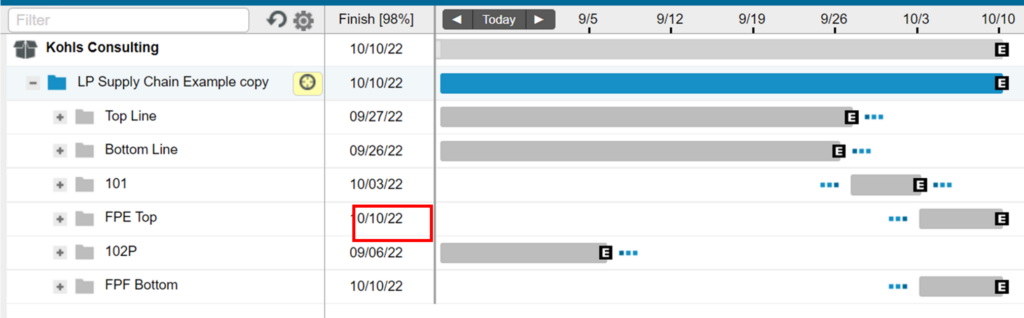

If we took this plan and applied it to the basic rules of variability and dependency, we would enter it into a less sophisticated tool with all of the resources in overdrive and without a best-case, worst-case range. This means that we may overschedule a critical resource because the planning tool cannot incorporate variability in those tasks. We would work to averages and predict this finish date to be 10/10.

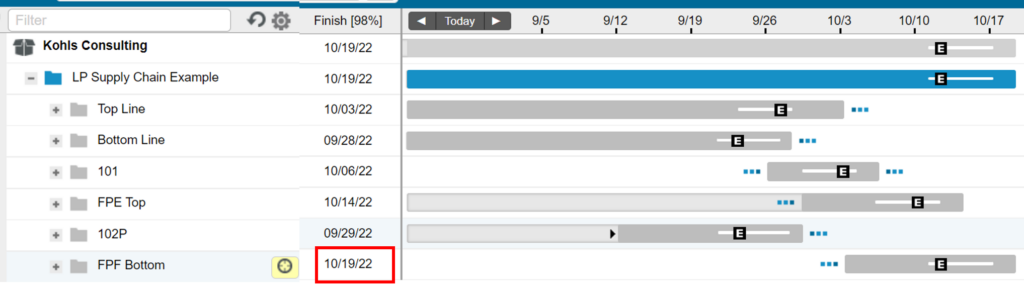

However, if we use LiquidPlanner, we can incorporate that wide range of uncertainty with best-case, worst-case planning. Which is much more accurate than an average of the two extremes.

We see different results when we include LiquidPlanner’s Critical Chain Project Management as part of their demand planning. The results are consistently longer than the typical results from simpler demand planning tools.

The end date has been extended to 10/19 with the uncertainty incorporated. Now we can see why we are consistently late on projects. Your timeline becomes even more realistic when incorporating dependency tracking on tasks and resources. Note the white bars inside the task – they show the variability of task completion. Finally, the E in the black box shows the average completion date – when we will get 50% completed on time. Obviously, we should be shooting more like 98% — perhaps higher.

Now that we have a more accurate lead time prediction, we can have a platform for continuous improvement, especially the waste of inventory and the impact on cash flow.

Demand Planning using LiquidPlanner’s sophisticated DDMRP methodology eliminates the chaotic forecasting process. The combination of using actual demand while incorporating variability in lead time and dependency planning allows you to plan more confidently and stay within budget. Improving demand planning is made easier with LiquidPlanner.

About the Author

Kevin Kohls is the leading authority in using the Theory of Constraints in the Auto Industry. He used LiquidPlanner successfully for engineering to order at Rex Materials to increase OTP by more than 95%. Kevin is also the author of Addicted to Hopium a book about the process of throughput and breaking the habit of guesswork. He can be contacted at kevin.kohls@yahoo.com. View Kevin’s LinkedIn here.

Kevin Kohls is the leading authority in using the Theory of Constraints in the Auto Industry. He used LiquidPlanner successfully for engineering to order at Rex Materials to increase OTP by more than 95%. Kevin is also the author of Addicted to Hopium a book about the process of throughput and breaking the habit of guesswork. He can be contacted at kevin.kohls@yahoo.com. View Kevin’s LinkedIn here.