While its use of Theory of Constraint (TOC) methods enabled Rex Materials to optimize its manufacturing operations, the company needed to address all the other steps that must take place prior to manufacturing in the engineer-to-order (ETO) process—thereby preventing Rex Materials from effectively optimizing its entire value stream. To address this, Rex Materials used LiquidPlanner to implement Critical Chain project management, a set of TOC methods that emphasizes the people and other resources required to execute project tasks. The company’s efforts to wrap its entire value stream within a real project management system has yielded several benefits, including faster delivery of ship dates, improved project plans, fewer calls and interruptions, shorter meetings, faster decision-making, reduced chaos and frustration, and greater business throughput.

Company

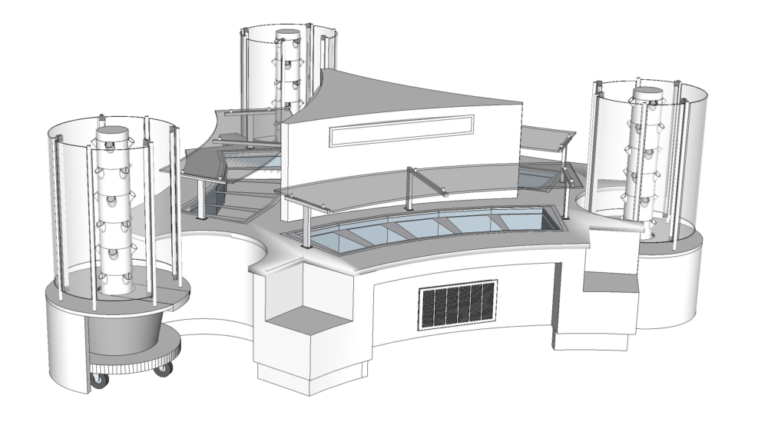

Rex Materials Group is a leading manufacturer of high-temperature materials systems and refractory (heat-resistant) materials—with applications ranging from high-temperature insulation and combustion chambers to molten metal handling. The company specializes in the development and delivery of custom-engineered solutions that utilize its PYROLITE® vacuum formed ceramic fiber, FUSIO2N (Fusion) fused silica, Pyroform HP™ insulating refractory, and RXTCON® ceramic/ceramic-metal matrix composite materials to meet each customer’s unique heat containment needs. Rex Materials is headquartered in Howell, Michigan, where it maintains research and development laboratories, a design engineering group, a basic tool shop, a prototype and small-volume manufacturing facility, a process development center, a customer service center, and administrative offices. The company’s two main production facilities are located in South Hill, Virginia and Council Grove, Kansas.

“What I really love about LiquidPlanner are the Dashboards. I created my own dashboard that loops and pulls in all the different projects and milestone dates,” he says. “I have a widget set up that shows upcoming milestones. I can look down that list and see I’ve got Brighton High School as the next deadline I have, and then it goes into the different elementary schools and things. The Dashboards really help me prioritize what’s coming at me and the tasks I’ve got to work on, so things don’t get out of control that way. The Dashboards are awesome.”

Challenge

Today, Rex Materials uses Theory of Constraint (TOC)1 management techniques in combination with Lean Principles to run every aspect of its business, allowing the company to deliver on-time and as-promised while reducing waste and increasing productivity. However, that wasn’t always the case. Prior to 2015, the company’s use of TOC was primarily focused on its manufacturing operations using Drum-Buffer-Rope—a manufacturing execution methodology based on the fact the output of a system can never be faster than the constraint of that system. This was implemented using a dedicated production system called Synchrono. While this approach enabled Rex Materials to optimize its manufacturing operations, it didn’t adequately address the other work and handoffs that must take place prior to manufacturing—thereby preventing the company from increasing its productivity and profitability.

Due to the highly specific needs of its customers, a large part of Rex Materials’ business is engineer-to-order. Under that process, customer inquiries for potential orders are handed-off to Engineering to review before a quote can be returned to the customer. Should the inquiry become an order, it flows back through Engineering to complete the necessary work, which can take anywhere from a few hours of effort to a few months. Most “new” custom-engineered orders also require some work by the tooling shop; for re-orders of the same product, previously built tools can simply be pulled off-the-shelf. Typically, the company has some 30 such “projects” in the pipeline at any given time.

Unhappy Customers…and Employees

Without any formal work management system to help coordinate and optimize all steps in this process, Rex Materials was unable to provide customers with a delivery date for each order until it was pulled into the engineering design phase—due mainly to the fact that those delivery dates could not be accurately estimated until that work had started. Customers were not happy with this approach and, if the company was busy, that only increased the lead time before a delivery date could be provided. Typically, it took one to four weeks to provide a delivery date after the initial customer inquiry. Without early visibility into delivery dates, Customer Service received a large number of calls per day asking, “Where’s my order… When will it ship?” Customer Service would then have to determine where in the queue that order was, often requiring several conversations to determine its state. Was it in Engineering or was it in the tool room? Had the work started yet and, if so, how much effort remained before a ship date could be generated?

To make matters worse, orders were frequently reprioritized by whichever customer was “yelling the loudest,” without a full understanding of how it would affect projected delivery dates for other quotes and orders in the pipeline. The end result: a highly reactive environment full of confusion and frustration. For example, manufacturing, which was at the tail of the chain, would often learn on a Friday afternoon that its people had to work overtime that weekend. Lack of visibility into the entire pipeline (and the work involved for each phase of each order) also meant that Rex Materials did not have the data needed to optimize profitability—for example, prioritizing an order that would require minimal engineering effort over one that, all other things considered equal, would require significantly more engineering effort.

Finding a Better Way

To address this issue, Rex Materials knew that it had to wrap the entire chain of events—from initial customer inquiry to shipment of the completed order—within a real work management/project management system. Initial attempts by outside consultants focused on extending the DBR-based manufacturing system into Engineering. However, the results were unsatisfactory because DBR is designed to manage production processes, not people. All that began to change in early 2015, when the company interviewed Kevin Kohls for a position as director of continuous improvement.

Prior to that, Kohls, who has a strong background in TOC, had spent significant time helping companies in the automotive industry improve throughput. “Management knew that improving current methods wasn’t going to solve the problem,” he recalls. “When we began to dive deeper into the issues during my interview, it became clear that they were attempting to apply Drum-BufferRope methods that were designed to pull materials through a production system to managing peoples’ work. I observed that they should be looking at Critical Chain project management, a set of TOC methods that emphasizes people and other resources required to execute project tasks, and was hired to make that happen.” Knowing that his first step would be to find a work management tool that could support, Kohls immediately began doing his research. His requirements included key Critical Chain methods such as:

- Managing resources as well as timing

- Resource contention across multiple projects

- Generation of the Critical Chain for the entire project portfolio (called Critical Path in LiquidPlanner terms), so that the company could know where to focus on improvement

- Identification of constraint resources, so that action can be taken to ensure they get help and obstacles are removed

- “What if” capability to test proposed solutions

- Accounting for variability—and creation of a time buffer to absorb variability

- Understanding the probability of finishing on time (50 percent, 90 percent, etc.)

Other requirements included:

- Crystal clear priorities

- A way for resources (people) to understand what tasks they needed to focus on first

- Cross-site collaboration (as needed to cover and tie together the company’s three locations)

- Fast to implement and learn

- Low cost

Solution

Kohls’s evaluation of Critical Chain-specific solutions, which included Exepron, ProChain, and Realization, didn’t lead to any clear winners. “There were only a few Critical Chain-specific solutions out there, and they certainly would have worked,” he recalls. “But many of them appeared to be designed for much larger companies, had complex dashboards that didn’t add much value, and/or would likely require expensive consultants and training. Essentially, I wanted a simpler solution that would let me implement Critical Chain—to the extent that I could identify what needed to be fixed before a project was going to be irrevocably late.”

Fortunately, while he was evaluating Critical Chain-specific solutions, Kohls also kept an eye out for other tools that had the required capabilities. He quickly dismissed several, including Microsoft Project, Wrike, SmartSheet, Asana, and Clarizen. His ultimate choice: LiquidPlanner, which, while it didn’t support all the requirements in his initial list, seemed close enough to give it a try. “LiquidPlanner had all the important Critical Chain features I needed, but wasn’t overkill,” explains Kohls. ”It was also easy to get started with, easy to use, and low-cost—making it low-risk and giving me an easy out if needed—so I decided to give it a try. I quickly learned how to use LiquidPlanner by simply watching the videos; the only formal training required was what I later developed to teach our own people about Critical Chain and how to implement it using LiquidPlanner.”

From Chaos to Order in 60 Days

Kohls started his 30-day free trial of LiquidPlanner in July 2015, simulating several fictional projects using real-world data. The results were positive, leading Kohls to solicit buy-in to use LiquidPlanner from the engineering department. “The problem we were trying to solve was already the highest priority at the company, so a formal business justification wasn’t needed,” explains Kohls. “We knew that the ability to generate a ship date when a PO was submitted—with 90-percent on-time performance—would make customers happier and give us a competitive edge, and LiquidPlanner was the least expensive and lowest-risk way to achieve that goal.”

Rex Materials purchased a LiquidPlanner subscription in August 2015. By the following month, the company was using LiquidPlanner for all engineer-to-order projects. Today, Rex Materials uses LiquidPlanner for all projects. To assist others at Rex Materials with coming up-to-speed on how to use LiquidPlanner for Critical Chain project management, Kohls developed a robust training program. “I put together classes to demonstrate Critical Chain concepts and methods—such as how multitasking, while sometimes necessary, can also be very damaging—and integrated LiquidPlanner into those classes with examples,” he explains. “I also created some games within LiquidPlanner; the small wins that people experienced from playing those games and succeeding in solving problems, such as how to handle variation, was a big confidence-booster. All-in-all, training people on Critical Chain was harder than training them on LiquidPlanner.”

How It Works Now

Today, new customer inquiries start with Customer Service, which uses a cut-and-paste template within LiquidPlanner to create a new project. That kicks off notifications to other teams, including Engineering, which scopes each project and estimates the work involved. By the time a price quote is ready, the company also has a high-confidence ship date for the order, which is passed back to the customer along with the price quote. To complement its new capabilities, Rex Materials established a quick, 10-minute daily teleconference that involves Customer Service, Tooling, Engineering, and both manufacturing plants. In that meeting, they review all projects that have been quoted. For any that are “red” in status—that is, that have less than a 98-percent probability of finishing on time—the team discusses those projects and determines whether any countermeasures should be implemented, such as changing priorities or working overtime. Key discussions and decisions during these meetings are captured using LiquidPlanner comments and notes.

Benefits

Rex Materials’ use of LiquidPlanner has changed the way it manages the order chain, from initial customer inquiry to shipment of finished product, and gives the company visibility into that entire process. “We’ve gone from reactive to proactive—or, put another way, from frantic to ‘no big deal,’” says Kohls. Specific improvements and benefits include:

- Faster delivery of accurate ship dates. In the past, it took from one to four weeks after a customer submitted an order before a ship date could be provided, depending on how busy the company was. Today, ship dates are provided in two to three days, along with the initial quote. What’s more, Rex Materials is hitting those estimated ship dates with greater than 95-percent on-time performance.

- Improved project plans. Through its implementation of Critical Chain, Rex Materials has also improved its project planning process. “The implementation forced us to improve our project plans due to deficiencies that became obvious very quickly,” says Keith Schultz, Engineer-to-Order Lead at Rex Materials.

- Fewer calls and interruptions. The number of daily calls received by Customer Service asking “Where’s my order?” has decreased from 10-15 calls per day to zero. This has also eliminated the need to interrupt Tooling and Engineering to determine the status of an order, saving what Kohls estimates to be “hours upon hours” of wasted, unproductive time. “Salespeople can even see projected delivery dates on their phones, which keeps them in the loop and enables them to focus on winning new deals instead of babysitting existing customer orders,” says Kohls.

- Shorter meetings and faster decision-making. Through its use of LiquidPlanner, Rex Materials has been able to transition from infrequent, poorly attended meetings full of frustration and finger-pointing to a quick, 10-minute daily meeting. “Re-prioritizing orders is now the exception rather than the rule,” says Kohls. “Furthermore, in considering such decisions, LiquidPlanner immediately shows us the impact that a change in priorities will have on all other orders.”

- Less chaos and frustration. With brief daily meetings now all that’s needed to keep everyone on the same page, Rex Materials has experienced a reduction in confusion and finger-pointing. “After we made the transition to LiquidPlanner and Critical Chain, the initial reaction for many was disbelief—they did not really think we could do it,” says Kohls. “Today it’s mainly smiles, especially within Customer Service. Even the authors of some in-house tools saw the rationale of the new process and started using LiquidPlanner with only some training videos.”

- Clear Priorities. Previously, in the midst of all the confusion, people had to guess at which project had the highest priority. For example, preventive maintenance and tool repair demanded the same resources needed for engineering work—often at a hidden cost to overall business efficiency. Today, people can see their top priorities for each day on their personalized My Work pages in LiquidPlanner, enabling them to know exactly what they need to do—and enabling others to hold them accountable—as all parts of the company work together to accomplish shared priorities.

- Greater business throughput. In the past, Engineering was the company’s main constraint to “getting more done” with existing resources. Today, as Kohls puts it, “We’re pumping more work through the system and our primary constraints have shifted from Engineering to Sales, meaning the only impediment to further business growth is the ability to win new orders. We’re even looking at dipping our toes into a new area of business with even longer lead-times. This is something we wouldn’t have any confidence in doing without a tool like the one we now have.”

- Repository for lessons learned. Rex Materials is using LiquidPlanner notes and comments to document what went wrong—and when it went wrong— for those very few projects that are late. “We have new engineers review those late projects and go through the Five Why problem-solving process, which generates Lessons Learned,” says Kohls. “This allows us to minimize the chances of the same mistake causing another project to be late. Daily comments for Red projects are also a huge help in that we don’t find ourselves struggling to remember what went wrong when and when; the comments we’ve captured in LiquidPlanner tell the entire story.”

- Other unexpected value. On top of all the above, Rex Materials is seeing some unforeseen perks from its decision to use LiquidPlanner. “We’re using LiquidPlanner checklists as a method to create My Work pages for resources that aren’t working on projects, which holds especially true for management,” explains Kohls. “We also like how LiquidPlanner tags have enabled us to correlate information, such as tying a project number to a part number. And we love the new resource report in LiquidPlanner, which makes any constraints readily apparent and enables us to take rapid action—such as bringing in part-time help early enough to make a difference.”

Looking back, Kohls feels that his company’s use of LiquidPlanner to facilitate Critical Chain project management has been a huge success. To others who may be considering a similar journey, he offers the following advice: “First, make sure to thoroughly understand Critical Chain, so you can avoid problems that have nothing to do with the software. Second, work to establish efficient routines, like our short and sweet daily meetings. Third, think big but start small, breaking your implementation into phases or modules. And finally, remember that speed of implementation is critical because, well, everything in business seems to change every day. If you can’t get the process working in short order, you won’t be able to get it working at all.”